A small flaw bump on upper heat press platen ruins custom shirt projects. These defects create patchy transfers and blank spots on garments. Fixing these problems saves time and materials in 2025.

Small flaw bump on upper heat press platen affects businesses of all sizes. Professional printing shops lose customers due to quality issues. Home crafters waste expensive vinyl on failed transfers.

Your heat press requires immediate attention when symptoms appear. The longer you ignore the planning problems, the worse they become. Early intervention prevents costly equipment replacement.

What Is a Small Flaw Bump On Upper Heat Press Platen

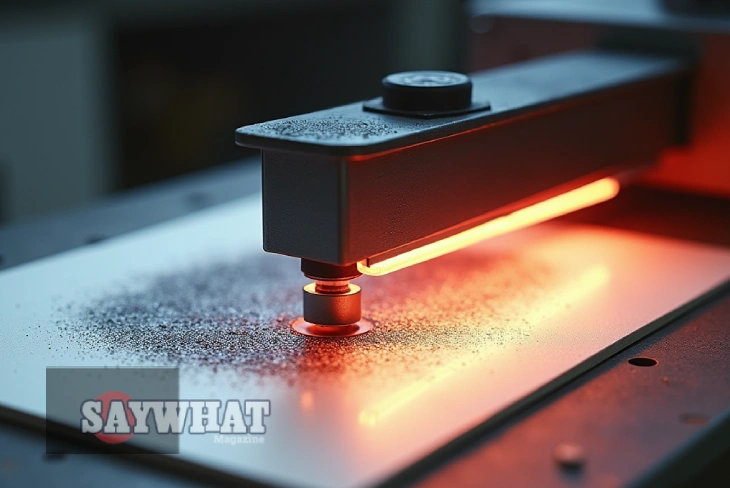

A small flaw bump on upper heat press platen is a raised surface imperfection. These range from tiny pinhead spots to larger pea-sized protrusions. They disrupt even heat distribution during pressing.

The bumps prevent proper contact between vinyl and fabric. This causes incomplete transfers and adhesion failures. Your designs show missing sections where bumps exist.

These defects waste materials and damage a business’s reputation. Customers expect perfect results from professional services. Early detection prevents these costly production issues.

Small flaw bump on upper heat press platen affects print quality consistently. The same spots fail repeatedly during production runs. This pattern helps identify plate problems quickly.

Heat transfer vinyl requires perfect surface contact to adhere properly. Any interruption in pressure creates weak spots. These weak areas peel or wash away prematurely.

How to Detect Small Flaw Bump On Upper Heat Press Platen

Run fingertips across the cool platen surface to feel irregularities. Focus on edges and high-use areas for best results. Small bumps often hide in these locations.

Inspect the platen surface under strong lighting. Angle the light to create shadows. This visual technique reveals slight imperfections otherwise invisible.

Test print on scrap fabric to identify problem spots. Missing ink patterns reveal platen flaws. This method saves your good materials during troubleshooting.

Use temperature strips to check heat distribution. Uneven readings indicate surface problems. This locates small flaw bump on upper heat press platen precisely.

Place thin paper across the entire platen surface. Close the press with light pressure. Inspect for uneven compression marks afterward.

Why Your Platen Developed Bumps

Manufacturing defects cause many initial platen problems. Residual metal and quality control issues create flaws. These appear early in machine life.

Heat presses endure extreme temperature cycling daily. This causes warping and denting over time. Commercial machines suffer most from this wear.

Adhesives and inks build up on the platens continuously. These residues create raised surfaces. They affect prints just like structural damage does.

Improper shipping and storage damage many heat presses. Stacking heavy items causes deformation. Following the manufacturer’s guidelines prevents these issues.

Small flaw bump on upper heat press platen develops from normal use. Even careful operators experience this problem eventually. Regular maintenance reduces occurrence rates.

DIY Solutions for Minor Platen Bumps

Clean your platen with non-abrasive cleaners first. Many bumps are hardened residue. Proper cleaning solves these common problems.

Heat the platen to normal operating temperature briefly. This softens stubborn residue for easier removal. Cool completely before attempting mechanical repairs.

Use silicone pads to work around small flaw bump on upper heat press platen. These accessories redistribute pressure during pressing. They provide temporary solutions while planning repairs.

Cool the platen completely before attempting structural repairs. Tap gently with a rubber mallet on affected areas. Apply careful heat and pressure to reshape minor deformations.

Create a heat press maintenance schedule for regular cleaning. Preventive care prevents most residue-based bumps. This schedule saves money long-term.

When to Call the Professionals

Severe deformations require professional intervention immediately. Multiple small flaw bump on upper heat press platen indicates serious issues. DIY methods cannot fix these problems.

Failed DIY repairs signal the need for expert help. Inconsistent curing despite adjustments shows serious damage. Complete platen replacement may be necessary.

Check warranty coverage before attempting major repairs. Specialty shops can resurface salvageable platens professionally. This prevents wasting materials on poor-quality transfers.

Heat press manufacturers offer replacement parts for covered equipment. This solves persistent small flaw bump on upper heat press platen issues. Professional servicing restores optimal performance.

Compare repair costs against replacement expenses carefully. Older machines may not justify expensive repairs. New technology offers significant improvements worth considering.

Prevent Future Platen Damage

Clean after each use to prevent residue accumulation. Let surfaces cool slightly before wiping. Use manufacturer-recommended cleaning products only.

Install protective silicone covers on your platens. These reduce direct contact with materials. They distribute pressure more evenly during operation.

Store heat presses with platens in the open position. Never stack items on the press. These habits prevent small flaw bump on upper heat press platen formation.

Follow all manufacturer maintenance guidelines strictly. Regular professional inspections catch developing issues. Preventive care extends equipment life significantly.

Train all operators on proper heat press techniques. Human error causes many platen problems. Consistent procedures reduce equipment damage considerably.

The Latest Industry Solutions in 2025

Choose precision-machined platens with quality certification. Modern manufacturing reduces defect likelihood. These advances minimize small flaw bump on upper heat press platen.

Diagnostic tools detect platen issues before production problems occur. Infrared thermometers reveal heat distribution anomalies. Early detection prevents material waste.

Anodized aluminum platens resist warping effectively. This material advancement represents cutting-edge technology. The investment delivers longer equipment life.

Smart platens with pressure monitoring now enter the market. These alert operators to developing issues. Prevention technology advances rapidly in 2025.

Modular heat press designs allow component replacement. This reduces repair costs significantly. Individual platen replacement extends machine lifespan considerably.

Conclusion

Small flaw bump on upper heat press platen impacts quality despite seeming minor. Regular maintenance prevents most platen problems effectively. New technologies continue improving equipment reliability.

Address platen issues quickly to save money long-term. Your heat press represents a substantial investment. Proper care maintains production quality for years to come.

Equipment manufacturers continue improving platen technology. Stronger materials and smarter designs reduce problems. The heat press industry advances rapidly in 2025.

For More Visit This Site: SayWhatMagazine